Core Guiding Principles

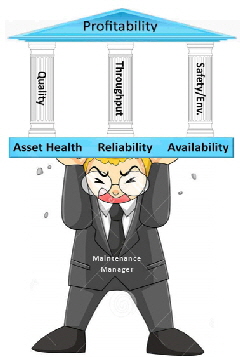

The Weight of the World

Principle #6

Organizations who have Reliability as a Core Value, actually achieve

Operational Reliability!

Principle #7

If you “Accept“, and by default, “Value Failure” then that is what you will achieve. When and ONLY WHEN Executive Management Teams STOP Accepting Failure as a natural part of operations, can they begin to realize their true potential in Operational Reliability...

We must transform the old mind-set of “things break and we must fix them quickly when they do”! To the more honest, new mind-set of “things continue to run and produce consistent results if properly

operated, monitored and maintained”!

We should not accept more than 5% of our maintenance downtime to be unplanned and or unscheduled downtime!

Principle #8

Industrial RCM / iRCM is a Standard Scientific Process as defined by the ICRCM and SAE which is proven to Reduce Maintenance costs, Increase Quality, Increase Safety, Increase Reliability and Increase Profitability!

Principle #9

Changing a Scientific Process will likely cause a breakdown in that process and its results, in any given application. You should not monkey around with iRCM process steps or procedures.- Do it, and Do it correctly and in the correct sequences and you can expect scientifically consistent results, DO it your own way and expect to get inconsistent results! DO it a little bit expect nothing! Expect your Maintenance Manager to try it a little here and there and see if it works first? Expect it not to work!

Does that work for Safety or Quality?

EXAMPLE: Let's just have 3 people wear safety glasses and see if it reduces eye injuries next quarter! Really?

Honestly, where does, this thinking come from???

Principle #10

Properly Trained and Certified Staff are your quickest and most direct way to implement iRCM effectively and in a sustainable way.!

Principle #11

If you implement iRCM properly you will already be approximately 66-75% of the way to reaching ISO 55000 certification compliance!

Principle #12

Reliability is an Organizational Function like Safety and Quality it is Everybody's Job and the Organization must take it seriously and support it from all departments.

Expecting a single department to produce Production related or

Operational Reliability is indicative of having NO understanding of how

Reliability is Produced or Achieved in the Real World...

Principle #6

Organizations who have Reliability as a Core Value, actually achieve

Operational Reliability!

Principle #7

If you “Accept“, and by default, “Value Failure” then that is what you will achieve. When and ONLY WHEN Executive Management Teams STOP Accepting Failure as a natural part of operations, can they begin to realize their true potential in Operational Reliability...

We must transform the old mind-set of “things break and we must fix them quickly when they do”! To the more honest, new mind-set of “things continue to run and produce consistent results if properly

operated, monitored and maintained”!

We should not accept more than 5% of our maintenance downtime to be unplanned and or unscheduled downtime!

Principle #8

Industrial RCM / iRCM is a Standard Scientific Process as defined by the ICRCM and SAE which is proven to Reduce Maintenance costs, Increase Quality, Increase Safety, Increase Reliability and Increase Profitability!

Principle #9

Changing a Scientific Process will likely cause a breakdown in that process and its results, in any given application. You should not monkey around with iRCM process steps or procedures.- Do it, and Do it correctly and in the correct sequences and you can expect scientifically consistent results, DO it your own way and expect to get inconsistent results! DO it a little bit expect nothing! Expect your Maintenance Manager to try it a little here and there and see if it works first? Expect it not to work!

Does that work for Safety or Quality?

EXAMPLE: Let's just have 3 people wear safety glasses and see if it reduces eye injuries next quarter! Really?

Honestly, where does, this thinking come from???

Principle #10

Properly Trained and Certified Staff are your quickest and most direct way to implement iRCM effectively and in a sustainable way.!

Principle #11

If you implement iRCM properly you will already be approximately 66-75% of the way to reaching ISO 55000 certification compliance!

Principle #12

Reliability is an Organizational Function like Safety and Quality it is Everybody's Job and the Organization must take it seriously and support it from all departments.

Expecting a single department to produce Production related or

Operational Reliability is indicative of having NO understanding of how

Reliability is Produced or Achieved in the Real World...

Principle #1

Large Organizations require Scientific Processes to manage Core Functions such as Production, Quality, Safety, etc. This is commonly referred to as Process-Based Management..

Principle #2

The Organizational Functions flow from the Organizational Core Values established by the Executive Management Team, Board of Directors, and CEO, etc.

The Core Values set the overall tone of the Organization and everybody knows how to handle things related to these Core Functions as guided by the Core Values...

Examples of Organizational Core Values

Commitment to Operational Safety

PSM, LOTO, LOPA, HAZOP Processes

A Commitment to Product Quality

ISO and or 6 Sigma Processes

A Commitment to Customer Service

CRM - Customer Service Processes

A Commitment to a Fair and Balanced Workplace

Standard HR Policies Processes

Principle #3

Any Core Business Function which does not have a Core Value Established by the Executive Team is basically ignored by the Organization.

This is because, absent a defined Value Stream, it is deemed without VALUE and therefore non-essential...

Principle #4

Setting a Low-Performance Value can be even more damaging than not setting one at all. If you set a low-performance value it will establish

low-performance practices within your Organizational Culture.

Principle #5

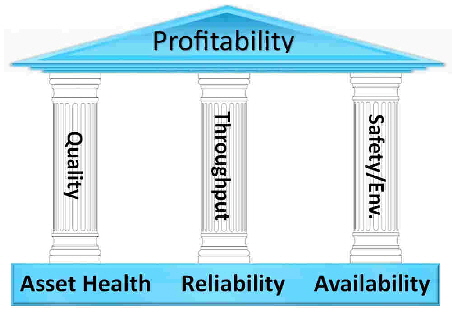

"The Missing Value" -You can see from the illustration below that the very foundation of all of your existing Core Values is

Asset Health and of course Availability!.

Large Organizations require Scientific Processes to manage Core Functions such as Production, Quality, Safety, etc. This is commonly referred to as Process-Based Management..

Principle #2

The Organizational Functions flow from the Organizational Core Values established by the Executive Management Team, Board of Directors, and CEO, etc.

The Core Values set the overall tone of the Organization and everybody knows how to handle things related to these Core Functions as guided by the Core Values...

Examples of Organizational Core Values

Commitment to Operational Safety

PSM, LOTO, LOPA, HAZOP Processes

A Commitment to Product Quality

ISO and or 6 Sigma Processes

A Commitment to Customer Service

CRM - Customer Service Processes

A Commitment to a Fair and Balanced Workplace

Standard HR Policies Processes

Principle #3

Any Core Business Function which does not have a Core Value Established by the Executive Team is basically ignored by the Organization.

This is because, absent a defined Value Stream, it is deemed without VALUE and therefore non-essential...

Principle #4

Setting a Low-Performance Value can be even more damaging than not setting one at all. If you set a low-performance value it will establish

low-performance practices within your Organizational Culture.

Principle #5

"The Missing Value" -You can see from the illustration below that the very foundation of all of your existing Core Values is

Asset Health and of course Availability!.

The Foundation of Profitability

What happens to Product Quality when equipment goes up and down?

What is the most dangerous time for most industrial plants?

Startups and Shutdowns...

So, if equipment is breaking down all of the time what is the impact on

Plant Safety?

Obviously Production Throughput and finally Profitability

both loose during breakdowns..

So the bottom line is, that the very FOUNDATION of all of the things that are your most critical Core Business Functions is

Asset Health, Reliability and Availability!

Agreed?

Have you made it a High Performance Value yet? Why Not?

Most Organizations do not fully understand what it takes to actually achieve

Operational Reliability...

We recommend CEOs, Executive Managers and Board Members,

attend Executive Training Course on

Operational Reliability and Risk Based Asset Management

OR

You can continue to ask your Maintenance Department Manager to handle all of this Executive Management stuff for you... World Class?

What happens to Product Quality when equipment goes up and down?

What is the most dangerous time for most industrial plants?

Startups and Shutdowns...

So, if equipment is breaking down all of the time what is the impact on

Plant Safety?

Obviously Production Throughput and finally Profitability

both loose during breakdowns..

So the bottom line is, that the very FOUNDATION of all of the things that are your most critical Core Business Functions is

Asset Health, Reliability and Availability!

Agreed?

Have you made it a High Performance Value yet? Why Not?

Most Organizations do not fully understand what it takes to actually achieve

Operational Reliability...

We recommend CEOs, Executive Managers and Board Members,

attend Executive Training Course on

Operational Reliability and Risk Based Asset Management

OR

You can continue to ask your Maintenance Department Manager to handle all of this Executive Management stuff for you... World Class?